Stainless Steel Hot Stamping | Stainless Steel Stamped Parts | Stainless Steel Hot Forged Components

Price $ 7.90/kilogram

High quality Stainless Steel Forging, Stainless Steel Stamping, Stainless Steel forged fittings, Stainless Steel stamped components from India

We are one of the leading manufacturers and exporters of Stainless Steel hot stamped and forged components from India. We have been supplying precision-engineered and durable Stainless Steel stamped and hot-forged parts to the global market for many decades. Our infrastructure is equipped with state-of-the-art forging hammers, hydraulic presses, and CNC finishing units. This enables us to deliver robust parts that meet the critical demands of industries like automotive, aerospace, oil & gas, electrical, and marine engineering. Our experienced metallurgists and engineers ensure every part meets international material, dimensional, and surface finish standards. We also offer Copper hot stamping forging and Brass stamping Brass stamped parts and Brass stamped components.

Overview

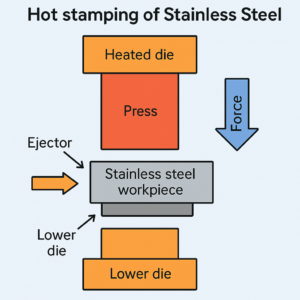

Stainless Steel hot stamping and hot forging are advanced metal shaping techniques that involve deforming Stainless Steel at elevated temperatures to achieve high-strength, corrosion-resistant components. These processes offer superior grain structure alignment, stress resistance, and mechanical integrity. Common applications include brackets, clamps, clevises, threaded inserts, pipe support parts, and heavy-duty fastening systems. The parts are often subject to post-forging operations like trimming, heat treatment, machining, and surface finishing.

Material Grades and International Standards

We process various grades of Stainless Steel based on strength, corrosion resistance, and forming behavior:

| Grade | Standard Equivalents | Typical Application |

|---|---|---|

| AISI 304 | ASTM A240, DIN 1.4301 | General-purpose corrosion resistance |

| AISI 316 | ASTM A276, JIS SUS316 | Marine and chemical exposure |

| AISI 410 | ASTM A276, DIN 1.4006 | High strength, moderate corrosion |

| AISI 420 | ASTM A276, IS 1570 | Cutlery, tools, wear-resistant parts |

| AISI 431 | ASTM A276, BS970 | High strength + corrosion resistance |

Mechanical Properties (Hot Forged AISI 316, Annealed)

| Property | Value |

| Tensile Strength | 515–620 MPa |

| Yield Strength | 205–275 MPa |

| Elongation | 30–40% |

| Hardness | 85–95 HRB |

| Density | 7.98 g/cm³ |

Manufacturing Process for Stainless Steel Hot Stamping | Stainless Steel Stamped Parts | Stainless Steel Hot Forged Components

Our manufacturing process combines precision and performance:

- Stainless Steel bars or billets are heated to 1000–1250°C

- Forging is performed using hydraulic or power hammers and press machines

- Parts are air-cooled or water-quenched as per mechanical requirements

- Flash trimming and shot blasting are done to remove scale and burrs

- Secondary operations include CNC turning/milling, drilling, and tapping

- Final heat treatment and surface finishing is applied as needed

Machinery Used

- 250T–1000T Hydraulic Forging Presses

- Pneumatic Hammers (1T to 5T)

- CNC Lathes and Milling Centers

- Shot Blasting and Sandblasting Units

- Heat Treatment Furnace (Annealing/Hardening)

- Coordinate Measuring Machines (CMM), Gauges, and Hardness Testers

Finish Options

- Shot Blasted / Matte

- Pickled and Passivated

- CNC Machined Surface

- Mirror Polished (for visible components)

- Electro-polished / Buffed (for sanitary or marine use)

Industries Using Stainless Steel Hot Forged Parts and Stainless Steel hot stamped components

- Automotive and Commercial Vehicles

- Oil & Gas Installations

- Power and Electrical Systems

- Food Processing and Dairy Equipment

- Marine and Shipbuilding

- Chemical Processing

Typical Parts Produced

- Pipe clamps and saddles

- Grounding clamps and fittings

- Valve bodies and flanges

- Anchor plates and support brackets

- Threaded nuts and tie rods

- Shaft ends and locking lugs

Dimensional Range and Tolerances

| Feature | Range |

| Forging Weight | 50 g to 8 kg |

| Part Diameter | 10 mm to 150 mm |

| Tolerances (machined) | ±0.1 mm to ±0.2 mm |

| Surface Finish (Ra) | As low as 1.6 µm (machined) |

| Draft Angle | 1.5° to 3° (for forging dies) |

Turnaround Time

Standard lead times are 4–6 weeks from die approval. We also offer accelerated deliveries for repeat parts or projects with existing tooling. Sample parts can be delivered in 12–15 working days.

Why Choose Our Stainless Steel Forged Components Forged Fittings and Stainless Steel stamping Stamped parts and Stainless Steel Stamped components

- Three decades of metallurgy and forming expertise

- Low tooling cost for small-to-medium volumes

- In-house die making and tool maintenance

- Custom finishing and surface treatment options

- Reliable international shipping and documentation

- Proactive customer communication and engineering support

Frequently Asked Questions (FAQs)

- Can you supply hot forged and machined Stainless Steel components?

- Yes, we offer turnkey solutions including CNC machining.

- What is the minimum order quantity?

- As low as 200 pieces depending on the size.

- Can you work with client-provided dies?

- Yes, we accept dies or develop new ones in-house.

- What surface treatments do you offer?

- Shot blasting, passivation, polishing, electropolishing.

- Do you offer material traceability?

- Yes, all materials come with test certificates and batch IDs.

- What quality inspections are done?

- Visual, dimensional, hardness, and surface checks. CMM on request.

- Do you export globally?

- Yes, including North America, Europe, Middle East, and ASEAN.

- What standards do your Stainless Steel forgings conform to?

- ASTM, DIN, IS, JIS, BS depending on customer requirement.

- Can you pack per OEM specifications?

- Yes, with custom logos, labels, and anti-corrosive packaging.

- Do you support 3rd-party inspections?

- Yes, through SGS, BV, TUV or any nominated agency.

Customer Testimonial

“We’ve worked with this supplier on Stainless Steel hot forged clamps and structural fittings for over 6 years. Their consistency, finish quality, and documentation are excellent. They truly understand the needs of North American OEM buyers.” — David M., Michigan, USA

Glossary of Terms

- Hot Stamping: Forming metal at elevated temperatures to reduce stress and increase strength

- Draft Angle: A slight angle on vertical surfaces to allow removal from forging dies

- Passivation: Chemical treatment that enhances corrosion resistance of Stainless Steel

- Pickling: Removal of oxide scale formed during forging

- CMM: Coordinate Measuring Machine used for precise dimensional verification

Packaging and Shipping

All components are cleaned and packed in VCI polybags or blister trays, placed inside heavy-duty cartons or wooden crates. Export markings include part number, heat number, and barcode labels. Palletized loads are shrink-wrapped for sea and air cargo.

Related Parts:

- Stainless Steel forging manufacturer India

- Hot forged pipe clamp parts exporter

- CNC machined Stainless forged brackets

- SS hot stamping automotive components

- Forged Stainless Steel fittings for marine use

- ISO-certified Stainless Steel forging supplier

- Copper Stamped and pressed parts

Looking for high-precision Stainless Steel hot stamped components? 📧 Email us or WhatsApp us today.

📁 Send your drawings or request a brochure today!