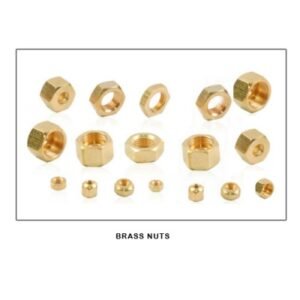

Brass Panel Nuts and Stainless Steel Panel Nuts

FOB Price – $11.20/Kg

Panel Nuts AKA Lock Nuts are specialized fasteners designed to secure components to panels, enclosures, or thin materials. Unlike standard nuts, panel nuts and lock nuts are often thinner and have a larger diameter, making them ideal for applications where space constraints or low-profile designs are necessary. They provide reliable fastening and can accommodate various thread sizes and panel thicknesses. Our range of Brass Panel Nuts and Stainless Steel panel nuts is well accepted in the international amrkets.

Brass Panel Nuts

Brass panel nuts are manufactured using high-grade brass alloys, known for their excellent corrosion resistance, conductivity, and machinability. Common grades include:

- C360 Brass: Known for its superior machinability and strength.

- C385 Brass: Excellent for decorative applications due to its smooth surface finish.

Stainless Steel Panel Nuts

Stainless steel panel nuts are favored for their high strength, durability, and resistance to corrosion, especially in harsh environments. Common grades include:

- 304 Stainless Steel: Offers excellent corrosion resistance and is suitable for most general applications.

- 316 Stainless Steel: Provides superior corrosion resistance, especially in marine or chemical environments.

Manufacturing Processes

Cold Forging

Cold forging is a common method for producing panel nuts. It involves shaping metal at room temperature, which enhances strength and surface finish. This process is particularly suitable for high-volume production due to its efficiency and consistency.

Machining

Machining is used for creating precise threads and intricate designs. This process is essential for custom or low-volume production and ensures tight tolerances and superior threading quality.

Finishes

Panel nuts are available in various finishes to enhance their appearance and resistance to corrosion:

- Brass Panel Nuts:

- Natural polished brass finish

- Nickel-plated for improved durability and aesthetics

- Chrome-plated for a sleek, reflective surface

- Stainless Steel Panel Nuts:

- Natural matte or polished finish

- Passivated for enhanced corrosion resistance

Threads

Panel nuts are available in a wide range of thread sizes and types to suit various applications, including:

- Unified Thread Standard (UTS): UNC, UNF, UNEF , UNS threads Common in the US market, with sizes like #4-40, #10-24, and 1/4-20.

- Metric Threads: Used globally, with sizes like M3, M6, and M12.

- Fine Threads: For applications requiring precise adjustment or high-strength fastening.

Applications

Brass and stainless steel panel nuts are used in a variety of industries, including:

- Electronics: Securing components in circuit boards and enclosures.

- Automotive: Fastening dashboards, panels, and interior components.

- Aerospace: Lightweight, corrosion-resistant solutions for thin panels.

- Construction: Fixing thin metal sheets or decorative panels.

- Marine: Stainless steel panel nuts for high corrosion resistance in saltwater environments.

- Industrial Equipment: Durable solutions for securing control panels and machinery components.

Advantages of Brass and Stainless Steel Panel Nuts

- Corrosion Resistance: Brass and stainless steel offer superior resistance to rust and corrosion.

- Strength: Stainless steel provides high tensile strength, while brass offers excellent machinability.

- Aesthetic Appeal: Both materials can be finished to create an attractive appearance suitable for visible installations.

- Customizable: Available in various thread sizes, shapes, and finishes to meet specific requirements.

| Thread Size | Hex Size (Inches) | Panel Thickness (Min – Max) | Common Material | Common Application |

|---|---|---|---|---|

| #4-40 | 5/16 | 0.02 – 0.06 | Brass and Stainless Steel | Electronics, Light Fixtures |

| #6-32 | 3/8 | 0.03 – 0.08 | Brass and Stainless Steel | Small Appliances, Electronics |

| #8-32 | 7/16 | 0.03 – 0.08 | Brass and Stainless Steel | Small Appliances, Electronics |

| #10-24 | 7/16 | 0.03 – 0.09 | Brass and Stainless Steel | HVAC, Furniture |

| #10-32 | 7/16 | 0.03 – 0.09 | Brass and Stainless Steel | Automotive, Furniture |

| 1/4-20 | 1/2 | 0.04 – 0.1 | Brass and Stainless Steel | Automotive, Machinery |

| 5/16-18 | 9/16 | 0.05 – 0.12 | Brass and Stainless Steel | Heavy Equipment, Construction |

| 3/8-16 | 11/16 | 0.05 – 0.14 | Brass and Stainless Steel | Heavy Equipment, Construction |

| 7/16-14 | 3/4 | 0.05 – 0.16 | Brass and Stainless Steel | Heavy Equipment, Construction |

| 1/2-13 | 7/8 | 0.06 – 0.2 | Brass and Stainless Steel | Industrial Equipment |

| 9/16-12 | 15/16 | 0.06 – 0.22 | Steel, Stainless Steel, Brass | Industrial Equipment |

| 5/8-11 | 1 1/16 | 0.08 – 0.25 | Steel, Stainless Steel, Brass | Heavy Equipment |

| 3/4-10 | 1 1/4 | 0.1 – 0.3 | Steel, Stainless Steel, Brass | Heavy Equipment, Industrial |

| 7/8-9 | 1 7/16 | 0.12 – 0.35 | Steel, Stainless Steel, Brass | Industrial Equipment |

| 1-8 | 1 1/2 | 0.12 – 0.4 | Steel, Stainless Steel, Brass | Industrial Equipment, Bridges |

| 1 1/8-7 | 1 11/16 | 0.15 – 0.45 | Steel, Stainless Steel, Brass | Construction Equipment, Bridges |

| 1 1/4-7 | 1 7/8 | 0.2 – 0.5 | Steel, Stainless Steel, Brass | Heavy Equipment, Bridges |

| M3 | 5.5mm | 0.5mm – 1.5mm | Steel, Stainless Steel, Brass | Electronics |

| M4 | 7mm | 0.6mm – 2mm | Steel, Stainless Steel, Brass | Electronics, Machinery |

| M5 | 8mm | 0.6mm – 2mm | Steel, Stainless Steel, Brass | Small Appliances, Electronics |

| M6 | 10mm | 0.8mm – 2.5mm | Steel, Stainless Steel, Brass | Furniture, Machinery |

| M8 | 13mm | 1mm – 3mm | Steel, Stainless Steel, Brass | Construction, Automotive |

| M10 | 16mm | 1.5mm – 4mm | Steel, Stainless Steel, Brass | Construction, Machinery |

| M12 | 18mm | 2mm – 5mm | Steel, Stainless Steel, Brass | Construction, Machinery |

| M14 | 21mm | 2mm – 6mm | Steel, Stainless Steel, Brass | Construction, Heavy Machinery |

| M16 | 24mm | 3mm – 7mm | Steel, Stainless Steel, Brass | Heavy Machinery |

| M18 | 27mm | 3.5mm – 8mm | Steel, Stainless Steel, Brass | Heavy Machinery, Bridges |

| M20 | 30mm | 4mm – 9mm | Steel, Stainless Steel, Brass | Bridges, Construction |

| M22 | 32mm | 5mm – 10mm | Steel, Stainless Steel, Brass | Heavy Machinery, Construction |

| M24 | 36mm | 6mm – 12mm | Steel, Stainless Steel, Brass | Heavy Machinery, Construction |

Q: What are Brass Panel Nuts and Stainless Steel Panel Nuts, and what are their applications?

A: Brass Panel Nuts and Stainless Steel Panel Nuts are precision fasteners used in electrical, mechanical, and instrumentation assemblies to secure panels, enclosures, and components. These nuts provide a strong, vibration-resistant hold and are commonly used in industries such as electrical equipment manufacturing, telecommunications, automotive, aerospace, and marine applications. Brass Panel Nuts are preferred for their electrical conductivity and corrosion resistance, while Stainless Steel Panel Nuts offer superior strength, durability, and oxidation resistance.

Q: What are the raw material grades used for Brass Panel Nuts and Stainless Steel Panel Nuts?

A: The choice of material grade depends on the application and required properties:

- Brass Panel Nuts: Manufactured using Brass Grades IS 319 (Type 1), CW614N, CZ121, C36000, or CW617N for high machinability and corrosion resistance.

- Stainless Steel Panel Nuts: Typically made from Stainless Steel 304, 316, 316L, and 303, ensuring excellent mechanical strength, wear resistance, and oxidation protection.

- Copper and Bronze Panel Nuts (for specialized applications): Made using Copper C110, Bronze C93200, and C95400, offering conductivity and high wear resistance.

Q: What is the manufacturing process for Brass Panel Nuts and Stainless Steel Panel Nuts?

A: The production process involves multiple precision steps to ensure the highest quality and durability:

- Raw Material Selection: High-quality Brass, Stainless Steel, Copper, or Bronze rods are selected based on the required specifications.

- Forging: The material is heated and shaped using precision forging dies, ensuring grain refinement for enhanced strength and durability.

- Machining: CNC and lathe machining are used to achieve precise dimensions, thread profiles, and tight tolerances.

- Thread Rolling or Cutting: The internal threading is created using advanced thread-cutting or rolling techniques for superior engagement and strength.

- Deburring and Finishing: All sharp edges and burrs are removed to ensure smooth handling and installation.

- Surface Finishing: The nuts are treated with different finishes based on application needs.

- Quality Inspection: Dimensional accuracy, material composition, and thread integrity are tested using precision measuring instruments.

Q: What types of surface finishes are available for Brass Panel Nuts and Stainless Steel Panel Nuts?

A: The finishing options vary based on corrosion resistance, aesthetics, and functional requirements:

- Brass Panel Nuts:

- Nickel Plating: Enhances corrosion resistance and provides a polished look.

- Tin Plating: Improves conductivity and oxidation resistance.

- Chrome Plating: Offers durability and an attractive metallic finish.

- Plain Brass Finish: Provides natural aesthetics and conductivity.

- Electropolishing: Creates a high-luster surface and removes surface imperfections.

- Stainless Steel Panel Nuts:

- Passivation: Removes contaminants and enhances oxidation resistance.

- Electropolishing: Provides a high-gloss finish and increased corrosion resistance.

- Black Oxide Coating: Reduces glare and enhances surface strength.

- Plain Stainless Steel Finish: Maintains the natural properties of Stainless Steel.

Q: How do Brass Panel Nuts compare with Stainless Steel Panel Nuts in terms of performance?

A: The choice between Brass Panel Nuts and Stainless Steel Panel Nuts depends on the specific application:

- Brass Panel Nuts:

- Superior electrical conductivity.

- Moderate mechanical strength.

- Good corrosion resistance, especially in dry and mildly humid environments.

- Ideal for electrical enclosures and applications requiring a non-magnetic material.

- Stainless Steel Panel Nuts:

- Exceptional mechanical strength and durability.

- High corrosion and oxidation resistance, even in extreme environments.

- Non-reactive to most chemicals and industrial fluids.

- Suitable for marine, automotive, and heavy-duty applications.

Q: What industries use Brass Panel Nuts and Stainless Steel Panel Nuts?

A: These nuts are widely used in industries such as:

- Electrical and Electronics: Secure components in control panels, circuit boards, and enclosures.

- Telecommunications: Provide stability in high-frequency and signal transmission applications.

- Automotive: Used in dashboard panels, connectors, and fastening parts.

- Aerospace: Ensures secure fastening in aircraft instrumentation and panels.

- Marine: Stainless Steel variants are preferred for saltwater resistance.

- Industrial Machinery: Provides strong fastening solutions in mechanical assemblies.

Q: How do the thread types affect the performance of Brass Panel Nuts and Stainless Steel Panel Nuts?

A: The threading method used in panel nuts plays a crucial role in load-bearing capacity and application efficiency:

- Standard Threads (UNC/UNF, Metric ISO): Common for general-purpose fastening in various applications.

- Fine Threads: Provides higher holding strength and vibration resistance in precision applications.

- Self-Locking Threads: Prevent loosening due to mechanical vibrations.

- Custom Threads: Manufactured per customer specifications for specialized requirements.

Q: How can I ensure I am choosing the right Brass Panel Nuts or Stainless Steel Panel Nuts for my application?

A: Consider the following factors while selecting panel nuts:

- Material: Choose Brass for electrical conductivity and Stainless Steel for strength and corrosion resistance.

- Size and Thread Type: Ensure compatibility with the mating components.

- Load-Bearing Capacity: Verify the mechanical properties for heavy-load applications.

- Corrosion Resistance: Select appropriate surface finishing based on environmental exposure.

- Certifications: Ensure compliance with ISO, RoHS, and ASTM standards.

By selecting the right Brass Panel Nuts or Stainless Steel Panel Nuts, you can improve the longevity, reliability, and performance of your assemblies across various applications.