Gunmetal Casting, Gunmetal Casting foundry from India!

Precision Gunmetal Casting Solutions – Premium Quality from India’s Leading Foundry

Gunmetal Casting Excellence: Technical Specifications & Services

Price $ 11.90/Kilogram

Premium Gunmetal Casting Solutions for Global Industries

We are one of the leading manufacturers and exporters of premium Gunmetal castings from India. We have been supplying high-precision Gunmetal components from our Bronze casting foundry- Gunmetal casting foundry to the world market for many decades. Our state-of-the-art foundry combines traditional metallurgical expertise with modern manufacturing techniques to deliver exceptional quality castings that meet the most stringent international standards. With over three decades of experience in the foundry industry, we have established ourselves as a trusted partner for companies across marine, industrial, architectural, and fluid handling sectors that require durable, corrosion-resistant bronze components with excellent mechanical properties. Our dedicated team of metallurgists, engineers, and quality control specialists works tirelessly to ensure that each casting meets exact specifications and performance requirements, regardless of complexity or volume.

Material Overview & Composition of Gunmetal Casting

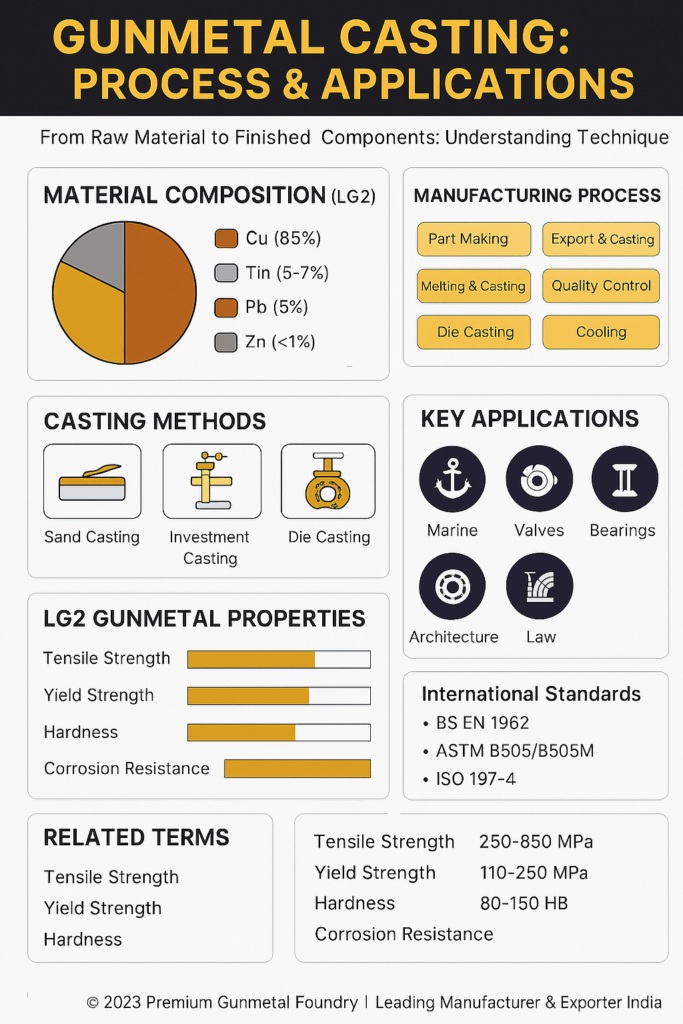

Gunmetal is a specialized Bronze alloy primarily composed of Copper, Tin, and Zinc, known for its excellent corrosion resistance, particularly in marine environments, combined with good mechanical properties and machinability. The traditional composition typically contains:

| Element | Percentage Range |

|---|---|

| Copper (Cu) | 85-90% |

| Tin (Sn) | 5-10% |

| Zinc (Zn) | 2-5% |

| Lead (Pb) | 0-2% (lead-free variants available) |

Standard Gunmetal Grades We Manufacture

Our foundry specializes in producing a comprehensive range of Gunmetal grades according to various international standards:

| Grade | Standard | Cu % | Sn % | Zn % | Pb % | Applications |

|---|---|---|---|---|---|---|

| LG2 | BS 1400 | 85 | 5 | 5 | 5 | Marine fittings, valve bodies, gears |

| G1 | BS 1400 | 86-90 | 9-11 | 1-3 | 0.5-1.5 | Pressure-tight castings |

| CDA 836 | ASTM B584 | 85 | 5 | 5 | 5 | Valves, pump components |

| CDA 903 | ASTM B584 | 88 | 8 | 4 | – | Marine hardware, wear applications |

| CDA 905 | ASTM B505 | 89 | 11 | – | – | High-pressure components |

| CuSn10Zn2 | EN 1982 | 86-89 | 9-11 | 1.5-3.5 | 0-0.5 | General engineering |

| ZCuSn10Pb1 | DIN 1705 | 86-89 | 9-11 | 1-3 | 0.5-1.5 | Fluid control systems |

| BC6 | JIS H5120 | 84-88 | 9-11 | 2-4 | 1-2 | Marine applications |

| G-CuSn10Zn | ISO 1338 | 86-90 | 9-11 | 1-3 | 0-1 | Corrosion-resistant applications |

| MTZ-5 | IS 318 | 85-88 | 9-11 | 2-4 | 0-2 | General engineering applications |

We also manufacture custom compositions to meet specific client requirements.

Manufacturing Processes for Gunmetal Casting

Our foundry employs multiple casting techniques to deliver the optimal results for different component requirements:

Gunmetal Sand Casting

Our primary method for large components and complex shapes, utilizing both green sand and chemically bonded sand systems. The process involves creating a pattern, packing sand around it to form a mold, removing the pattern, and pouring molten Gunmetal into the cavity. Sand casting offers excellent versatility for producing components ranging from valve bodies to pump housings, with good dimensional control and the ability to cast components with complex internal passages. Our precision molding department maintains tight dimensional control while allowing for excellent surface finish on complex geometries.

Gunmetal Centrifugal Casting

Specialized for cylindrical components such as bushings, bearings, and sleeves. In this process, molten Gunmetal is poured into a rotating mold where centrifugal force distributes the metal against the mold wall. This technique creates dense, porosity-free castings with excellent mechanical properties, directional solidification, and superior wear resistance. Particularly suitable for pressure-tight components, the process yields fine-grained microstructure at the wearing surface, enhancing performance in applications such as bushings and cylindrical liners.

Gunmetal Investment Casting

For components requiring superior surface finish and tight tolerances, we employ the investment casting process. This technique uses a wax pattern that is coated with ceramic material to form a shell. After the wax is melted out, molten Gunmetal is poured into the cavity. Investment casting produces near-net-shape components with excellent surface finish, minimal draft angles, and the ability to create complex, thin-walled structures that would be difficult to achieve with other methods. Ideal for architectural hardware, marine fittings, and precision components.

Gunmetal Shell Molding

This precision technique utilizes thin, thermally-cured shells made of sand mixed with thermosetting resin. Shell molds provide excellent dimensional accuracy, smooth surfaces, and good reproducibility. The process is particularly valuable for medium-sized Gunmetal components requiring better surface finish than conventional sand casting but without the cost of investment casting. Components produced via shell molding exhibit consistent wall thickness, good detail reproduction, and reduced machining requirements, making the process ideal for valve components and precision hardware.

Continuous Casting

For producing standard profile bars, tubes, and rods with consistent metallurgical properties throughout the length.

Process Flow

- Pattern Making: Precision wooden, metal, or 3D-printed patterns created based on client drawings.

- Mold Preparation: Sand preparation, molding, and core making.

- Metal Preparation: Charging, melting, and composition adjustment.

- Pouring: Temperature-controlled pouring of molten metal into prepared molds.

- Solidification and Cooling: Controlled cooling to ensure optimal metallurgical properties.

- Shakeout: Removal of castings from molds.

- Cleaning and Fettling: Shot blasting, grinding, and removal of gates and risers.

- Heat Treatment: When required for specific property enhancement.

- Machining and Finishing: CNC machining, grinding, polishing as per specifications.

- Quality Control: Dimensional inspection, NDT testing, chemical analysis, mechanical testing.

- Surface Treatment: Application of protective coatings if required.

- Packaging and Dispatch: Custom packaging according to client requirements.

Advanced Machinery & Equipment

Our modern foundry is equipped with state-of-the-art machinery to ensure consistent quality:

| Equipment Type | Specifications | Capabilities |

|---|---|---|

| Induction Melting Furnaces | 250 kg – 2 tons capacity | Temperature control ±5°C, homogeneous composition |

| Spectrometer | Full elemental analysis | Real-time composition control |

| Sand Mixers | High-speed Intensive mixers | Consistent sand properties |

| Molding Machines | DISA and HMC machines | Precise mold creation, high production rates |

| CNC Core Shooters | Programmable core parameters | Complex internal cavity formation |

| Automatic Pouring Systems | Programmable pour rate | Consistent filling, reduced defects |

| Heat Treatment Furnaces | Programmable cycles | Precise property development |

| CMM Machines | Accuracy to 0.01mm | Comprehensive dimensional verification |

| X-Ray Inspection | Digital imaging system | Internal defect detection |

| CNC Machining Centers | 3, 4, and 5-axis capability | Complex machining operations |

| Surface Finishing Equipment | Multiple finishing options | Customized surface appearance and properties |

| Environmental Control Systems | Dust collection, metal recovery | Sustainable manufacturing practices |

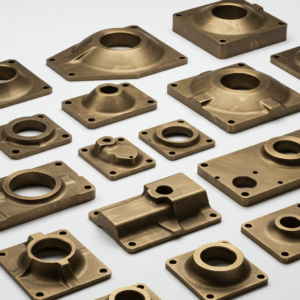

Typical Parts Produced

Our foundry specializes in a wide range of Gunmetal components, including but not limited to:

| Component Type | Weight Range | Industries Served |

|---|---|---|

| Marine Propellers | 0.5 kg – 500 kg | Marine, Shipping |

| Valve Bodies | 0.1 kg – 150 kg | Oil & Gas, Water Management |

| Pump Components | 0.2 kg – 80 kg | Industrial, Chemical Processing |

| Bushings and Bearings | 0.05 kg – 30 kg | Manufacturing, Heavy Equipment |

| Gears and Worm Wheels | 0.1 kg – 50 kg | Industrial Machinery |

| Architectural Hardware | 0.05 kg – 20 kg | Construction, Restoration |

| Historical Reproductions | 0.1 kg – 300 kg | Restoration, Museums |

| Decorative Components | 0.05 kg – 15 kg | Architectural, Luxury Products |

| Impellers | 0.2 kg – 100 kg | Pumping, Fluid Handling |

| Pipe Fittings | 0.1 kg – 25 kg | Plumbing, Industrial Systems |

High-Performance Gunmetal Marine Propellers

Technical Specifications:

| Parameter | Specification Range |

|---|---|

| Diameter | 100mm – 2000mm |

| Number of Blades | 3, 4, or 5 |

| Pitch | Variable, fixed, or adjustable |

| Hub Configuration | Various tapers and mountings available |

| Material | LG2, G1, or Custom Alloy |

| Surface Finish | Machined, Polished, or SuperPolished™ |

| Balancing | Static and Dynamic to ISO 1940 G6.3 |

| Maximum Operating Speed | Up to 3600 RPM (size dependent) |

Performance Characteristics:

- Excellent cavitation resistance

- Superior corrosion resistance in seawater

- High structural integrity under dynamic loading

- Optimized hydrodynamic efficiency

- Extended service life in marine environments

Dimensional Tolerances

Our manufacturing processes adhere to tight tolerances to ensure component performance and interchangeability:

| Dimension Range | Sand Casting | Investment Casting | Centrifugal Casting |

|---|---|---|---|

| Up to 50mm | ±0.8mm | ±0.25mm | ±0.5mm |

| 51-150mm | ±1.2mm | ±0.5mm | ±0.8mm |

| 151-300mm | ±1.8mm | ±0.8mm | ±1.2mm |

| 301-500mm | ±2.5mm | ±1.2mm | ±1.5mm |

| Over 500mm | ±3.5mm | – | ±2.0mm |

Special Tolerance Requirements: We can achieve tighter tolerances through controlled casting techniques and subsequent machining operations. Please consult our engineering team for specific requirements.

Surface Finish

We offer various surface finishes depending on application requirements:

| Finish Type | Ra Value | Applications |

|---|---|---|

| As-Cast | 12.5-25 μm | Non-critical surfaces |

| Shot Blasted | 6.3-12.5 μm | General industrial |

| Machined | 1.6-6.3 μm | Mechanical interfaces |

| Ground | 0.8-1.6 μm | Mating surfaces |

| Polished | 0.2-0.8 μm | Marine, decorative |

| SuperPolished™ | <0.2 μm | Hydrodynamic surfaces |

Material Properties

Standard Gunmetal (LG2/BS 1400) Properties:

| Property | Value | Test Method |

|---|---|---|

| Tensile Strength | 230-280 MPa | ASTM E8 |

| Yield Strength | 120-150 MPa | ASTM E8 |

| Elongation | 13-18% | ASTM E8 |

| Hardness | 70-90 HB | ASTM E10 |

| Density | 8.7-8.8 g/cm³ | ASTM B311 |

| Electrical Conductivity | 8-10% IACS | ASTM B193 |

| Thermal Conductivity | 42-50 W/m·K | ASTM E1225 |

| Melting Range | 880-1000°C | DTA |

| Modulus of Elasticity | 90-110 GPa | ASTM E111 |

| Poisson’s Ratio | 0.33 | ASTM E132 |

| Coefficient of Thermal Expansion | 18.5 × 10⁻⁶/°C | ASTM E228 |

| Specific Heat Capacity | 376-385 J/kg·K | ASTM E1269 |

Quality Assurance & Testing

Our comprehensive quality management system is certified to ISO 9001:2015 standards. Every casting undergoes a rigorous inspection process:

Chemical Analysis:

- Optical emission spectrometry for complete compositional verification

- Carbon and sulfur analysis by combustion method

Mechanical Testing:

- Tensile testing (UTS, yield strength, elongation)

- Hardness testing (Brinell, Rockwell)

- Impact testing where applicable

Non-Destructive Testing:

- Visual inspection to ASTM A802

- Liquid penetrant testing to ASTM E165

- Radiographic testing to ASTM E1742

- Ultrasonic testing to ASTM E587

- Pressure testing for hydraulic components

Dimensional Inspection:

- CMM measurement of critical dimensions

- Optical measurement systems

- Custom gauging for high-volume production

Certifications Provided:

- Material Test Certificates to EN 10204 3.1

- Dimensional Inspection Reports

- NDT Reports

- Heat Treatment Charts (where applicable)

Industries Served

Our Gunmetal castings serve critical applications across multiple industries:

Marine Industry:

- Propellers, rudder components, seawater valves

- Corrosion-resistant fittings and hardware

- Pump components for marine applications

Oil & Gas:

- Valve bodies and components

- Pressure-containing equipment

- Corrosion-resistant fittings

Water Management:

- Control valves and regulators

- Pump components

- Fluid handling equipment

Historical Restoration:

- Period-accurate reproductions

- Architectural hardware

- Decorative elements

Heavy Engineering:

- Bearings and bushings

- Wear components

- Gear systems

Architecture & Construction:

- Decorative hardware

- Structural components

- Period features

Turnaround Time & Production Capacity

We understand the importance of timely delivery in your supply chain:

Standard Lead Times:

- Prototype/Sample Development: 2-3 weeks

- Low-Volume Production (up to 100 pieces): 3-4 weeks

- Medium-Volume Production (100-500 pieces): 4-6 weeks

- High-Volume Production (500+ pieces): 6-8 weeks

Rush Order Service: We offer expedited manufacturing for urgent requirements. Please contact our sales team for availability and pricing.

Production Capacity:

- Monthly casting capacity: 150 tons

- Annual casting capacity: 1800 tons

- Pattern storage capacity: 15,000+ patterns

Why Choose Our Gunmetal Castings?

Technical Excellence:

- Three decades of specialized experience in Bronze and Gunmetal casting

- Metallurgical expertise across multiple alloy systems

- Advanced production technology and equipment

- Comprehensive testing and certification capabilities

Supply Chain Advantages:

- Consistent quality conforming to international standards

- Reliable delivery performance (98.7% on-time delivery record)

- Competitive pricing structure

- Flexible production scheduling

Customer Service:

- Dedicated technical support from experienced engineers

- Digital collaboration tools for design review and approval

- Regular production updates and communication

- Responsive inquiry handling (24-hour response guarantee)

Global Capabilities:

- Experience serving clients across 30+ countries

- Compliance with international standards and specifications

- Multi-language technical support

- Comprehensive export documentation handling

Customization Flexibility:

- Custom alloy development capabilities

- Proprietary process adaptations for challenging components

- Specialized packaging and marking systems

- Tailored quality control protocols

Our Unique Selling Propositions

Metallurgical Excellence: Our in-house metallurgical laboratory allows us to develop and refine custom Gunmetal compositions for specialized applications, delivering enhanced performance characteristics beyond standard grades.

Integrated Manufacturing: From pattern making to finished components, our vertical integration ensures consistent quality control and eliminates coordination challenges associated with multiple vendors.

Design Collaboration: Our engineering team offers design-for-manufacturing consultation to optimize component design for performance, cost-efficiency, and production feasibility.

Sustainable Manufacturing: We implement advanced metal recovery systems, energy-efficient melting technologies, and waste reduction practices to minimize environmental impact while maintaining competitive pricing.

Global Supply Capability: With established logistics partnerships and export expertise, we offer reliable delivery worldwide with comprehensive shipping documentation and customs support.

Inventory Management Solutions: For regular clients, we offer Kanban and Just-In-Time delivery options with maintained safety stock levels to ensure continuous supply without excessive inventory costs.

Packaging & Shipping

Standard Packaging Options:

- Industrial wooden crates (fumigated for international shipping)

- Reinforced cardboard boxes with custom inserts

- Vacuum-sealed moisture barrier packaging for long-term storage

- Custom palletization for efficient handling

Protection Methods:

- VCI (Volatile Corrosion Inhibitor) wrapping

- Oil coating for machined surfaces

- Custom-designed component separators

- Shock-absorbent packaging for delicate components

Customization Available:

- Customer-branded packaging

- Special labeling and identification systems

- Custom documentation packages

- Specialized container loading arrangements

Shipping Methods:

- Air freight for urgent deliveries

- Sea freight for economical shipping

- Door-to-door courier for smaller shipments

- Consolidated shipping options for regular orders

Frequently Asked Questions

Q: What is the difference between Gunmetal and standard Bronze?

A: While both are Copper-based alloys, traditional Gunmetal typically contains 85-88% Copper, 5-10% Tin, 2-5% Zinc, and sometimes 2-5% Lead, giving it excellent corrosion resistance and good mechanical properties. The LG2 grade specifically contains 85% Copper, 5% Tin, 5% Zinc, and 5% Lead. Standard Bronze usually has a simpler Copper-Tin composition without Zinc or Lead. The addition of Zinc in Gunmetal improves fluidity during casting, while Lead enhances machinability.

Q: How does Gunmetal perform in marine environments?

A: Gunmetal exhibits excellent corrosion resistance in seawater and marine environments due to its high Copper and Tin content. It forms a protective patina that prevents further corrosion, making it ideal for marine applications such as propellers, valves, and fittings exposed to seawater.

Q: Can you manufacture lead-free Gunmetal components?

A: Yes, we produce lead-free Gunmetal variants that comply with international regulations such as the EU RoHS directive. These formulations maintain excellent mechanical properties while eliminating lead content through careful alloy balancing and process control.

Q: What are the minimum and maximum casting sizes you can produce?

A: Our foundry can produce Gunmetal castings ranging from as small as 50 grams up to 500 kilograms in single pieces. For components outside this range, please consult our engineering team for feasibility assessment.

Q: How do you ensure consistent quality across production batches?

A: We maintain strict quality control through multiple measures: spectrometric analysis of each melt, standardized process parameters, regular equipment calibration, comprehensive inspection protocols, and statistical process control methods to track key variables.

Q: What type of certification do you provide with shipments?

A: Standard documentation includes Material Test Certificates (EN 10204 3.1), dimensional inspection reports, and Certificate of Conformance. Additional certification such as NDT reports, pressure test certificates, and specialized testing results are available upon request.

Q: Can you match existing components for replacement parts?

A: Yes, we specialize in reverse engineering existing components when original drawings are unavailable. Using advanced 3D scanning, metallurgical analysis, and performance testing, we can create replacements that match or exceed the performance of original parts.

Q: What design assistance do you offer for new components?

A: Our engineering team provides comprehensive design-for-manufacturing support, including draft angle optimization, gating system design, solidification simulation, wall thickness recommendations, and tolerance guidance to ensure castability and performance.

Q: How do you handle international shipping and customs requirements?

A: We have extensive experience with international logistics and provide complete export documentation including packing lists, commercial invoices, certificates of origin, and material certifications. Our logistics team can arrange shipping to any global destination and navigate customs requirements.

Q: What are your minimum order quantities?

A: While we specialize in medium to high-volume production, we understand the need for smaller quantities, especially for specialized components. Our minimum order quantities vary by component complexity and size, but we can accommodate orders as low as 5-10 pieces for many standard components.

Q: Do you offer sampling before full production?

A: Yes, we recommend the production of sample castings for new designs. These samples undergo comprehensive testing and can be provided to clients for their evaluation and testing before proceeding with full production runs.

Customer Testimonials

“We’ve been sourcing precision Gunmetal components from this foundry for our marine equipment for over eight years. Their consistent quality and ability to meet our exact specifications have made them an invaluable partner in our supply chain. Their technical support and willingness to collaborate on design improvements have significantly enhanced our product performance.” – R.Thompson, Procurement Director, ****M Systems, USA

“As a restoration specialist dealing with historical buildings, finding authentic Gunmetal castings that match original specifications is crucial. This foundry has consistently delivered exceptional quality reproductions that are virtually indistinguishable from the original 19th-century components. Their metallurgical knowledge and craftsmanship are truly impressive.” – Elizabeth Harrington, USA

“The custom Gunmetal alloy developed by their metallurgical team solved a persistent corrosion issue we were experiencing in our chemical processing equipment. Their technical expertise and responsive communication throughout the development process demonstrated why they’re leaders in this specialized field.” – Michael Chen, Engineering Manager, UK

Glossary of Technical Terms

Alloy – A metal made by combining two or more metallic elements to enhance properties such as strength, corrosion resistance, or castability.

Centrifugal Casting – A casting technique where molten metal is poured into a rotating mold, using centrifugal force to distribute the metal and create dense, porosity-free castings.

Dezincification – A corrosion process where Zinc is selectively removed from Brass or Gunmetal, leaving a weakened, porous Copper structure.

Gun metal – A type of Bronze alloy traditionally composed of Copper, Tin, Zinc, and sometimes Lead. Originally used for making cannons (hence the name), it offers excellent corrosion resistance, good wear properties, and favorable casting characteristics making it ideal for marine applications and fluid control systems.

LG2 – A specific grade of Gunmetal defined in British Standard BS 1400 with a composition of approximately 85% Copper, 5% Tin, 5% Zinc, and 5% Lead. LG2 is widely used for pressure-tight components, marine fittings, and valve bodies due to its excellent corrosion resistance and good machinability.

Investment Casting – Also known as lost-wax casting, a precision casting method using expendable wax patterns coated with ceramic material to form molds.

Patina – A surface layer that forms on Copper alloys through oxidation, often providing protective qualities and distinctive coloration.

Porosity – Void spaces or gas pockets within a casting that can affect mechanical properties and pressure tightness.

Riser – A reservoir of molten metal connected to a casting to compensate for solidification shrinkage.

Sand Casting – A casting process using sand as the mold material, packed around a pattern that is removed before pouring.

Tensile Strength – The maximum stress that a material can withstand while being stretched before breaking.

Yield Strength – The stress at which a material begins to deform plastically rather than elastically.

Related Parts:

Marine Bronze Castings, Corrosion-Resistant Bronze Alloys, Historical Bronze Reproductions, Naval Bronze Components, Gunmetal Marine Propellers, Tin Bronze Casting, Bronze Valve Components, Leaded Gunmetal, BS1400 LG2 Castings, CDA 836 Bronze, Seawater-Resistant Bronze, Investment Cast Bronze, Sand Cast Gunmetal, High-Tin Bronze Castings, Bronze Pump Components, Marine Gunmetal Fittings, G1 Bronze Castings, Custom Bronze Alloys, Architectural Bronze Hardware, Gunmetal Bushings and Bearings.

Contact Us For Your Gunmetal Casting Requirements

Request a Quote Today!

- Email: Send us an email for detailed quotations or product brochures

- Phone: Call us for a quick reply.

- WhatsApp: Send us a WA message for quick responses and technical discussions

- Sample Request: Fill out our online form to request material samples or prototype development

Our technical team is available to discuss your specific requirements and provide tailored solutions for your Gunmetal casting needs.

ISO 9001:2015 Certified Manufacturing Facility Approved Supplier to Major Marine and Industrial OEMs Worldwide