Copper Stamping | Copper Stamped Parts | Copper Stamped Components

PRICE: $ 11.60/kilogram

High quality Copper pressed and stamped parts and Copper Stamped components from India!

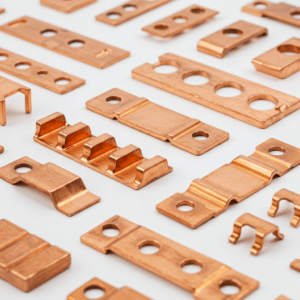

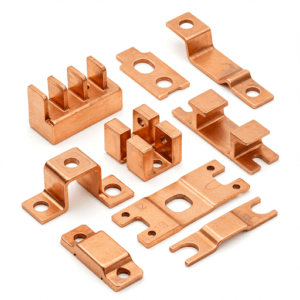

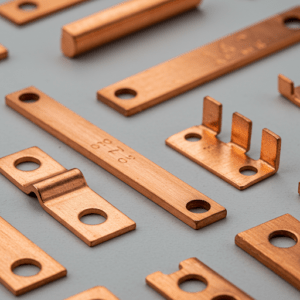

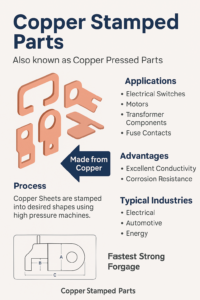

We are one of the leading manufacturers and exporters of Copper Stamped Components, Copper stamping and Copper stamped parts from India. We have been supplying high-conductivity, dimensionally precise Copper stamped parts to the world market for many decades. Our stamped Copper components are widely used in electrical and electronics industries including switchgear, electrical motors, cable management systems, power transformers, and industrial fuse assemblies. Our strength lies in our ability to offer customized solutions with short lead times, export-friendly packaging, and strict quality controls. Whether you require complex progressive die components or simple blanks and tags, we offer scalable stamping services with global reliability.

Overview

Copper stamping refers to the cold-forming of Copper sheet or strip into complex geometries using precision dies and stamping presses. These components are critical in electrical applications due to Copper’s excellent thermal and electrical conductivity. Common uses include fuse contacts, cable terminals, busbar segments, earth tags, transformer lead frames, and rotor/motor contacts. Depending on application requirements, the stamping process may include blanking, piercing, bending, embossing, coining, and parting in one or multiple stages. Our range of Copper pressed parts and pressed components as well as Brass stamped parts is well accepted in US and Europe. We also do Copper hot forging and hot stamping for electrical needs.

Material Grades and Specifications

We work with high-purity and alloyed Copper grades meeting global standards:

| Grade | Composition / Type | Standards | Key Properties |

|---|---|---|---|

| ETP Copper (C11000) | Cu ≥ 99.90%, Oxygen-bearing | ASTM B152, IS 191 | Excellent conductivity, general purpose |

| OFC (C10200) | Cu ≥ 99.95%, Oxygen-free | ASTM B187, JIS H3100 C1020 | Superior conductivity, critical electronics |

| CuZn Alloy C23000 | Cu 85%, Zn 15% | ASTM B36 | Higher strength, moderate conductivity |

| C194 High-Strength Cu | Cu-Iron alloy | ASTM B465 | Strength + conductivity, motor uses |

Mechanical Properties of ETP Copper (C11000, Annealed)

| Property | Value |

| Electrical Conductivity | ≥ 100% IACS |

| Tensile Strength | 210–250 MPa |

| Yield Strength | 65–100 MPa |

| Elongation | 25–40% |

| Hardness | 40–60 HRB |

Manufacturing Process

Copper coils or sheets are uncoiled, straightened, and fed into:

- High-speed or hydraulic presses for blanking/forming

- Progressive dies for multistage forming and parting

- Fine Blanking, Deep Drawing, transfer stamping

- Followed by deburring, surface finishing, and plating

- Optional value-adding operations: drilling, welding, forming, joining

- All parts undergo visual and dimensional inspections

Machinery Used

- Power Presses (10–160T)

- Pneumatic/Mechanical Presses for high volume

- Progressive Tooling Lines

- Wire EDMs and Surface Grinders for toolmaking

- Vibratory Tumblers and Buffing Wheels

- Digital Verniers, Vision Gauges, and Profile Projectors

Finish Options

- Natural Copper Finish (degreased or coated)

- Electro Tin / Nickel Plated

- Silver Plated (for high conductivity parts)

- Buffed, Deburred, and Mirror Finish (on request)

Industries Using Copper Stamped Parts

Our stamped Copper parts are used extensively in:

- Electrical Switches and Control Panels

- Power and Distribution Transformers

- Cable Gland Earth Tag Assemblies

- Electrical Motors and Generator Contact Parts

- Copper Fuse Holders and Fuse Link Contacts, Copper Fuse contacts

- Renewable Energy and Battery Assemblies

- Copper cable lugs Copper cable terminals

Typical Parts Produced

- Copper Earth tags and saddle tags for cable glands

- Copper fuse clips and blades

- Rotor winding and motor brush parts

- Contact arms, switch linkages, and terminals

- Busbar joints and anchor clips

- Customized Copper shims and washers

- Copper cable lugs Copper cable shoes Copper cable terminals

Dimensional Range and Tolerances

| Feature | Range / Tolerance |

| Thickness | 0.2 mm to 3.2 mm |

| Maximum Part Size | 300 mm × 300 mm |

| Dimensional Tolerance | ±0.05 mm to ±0.2 mm |

| Hole Diameter Tolerance | ±0.05 mm |

| Flatness | ≤ 0.15 mm per 100 mm |

| Surface Roughness | Ra 0.8–1.6 µm (plated) |

Turnaround Time

Our typical delivery time is 4 to 6 weeks from final drawing/tool approval. Samples are delivered in 10–15 days. Repeat orders and standard parts are expedited within 2–3 weeks, supported by strong vendor and logistics networks.

Why Choose Us

- 30+ years of precision stamping expertise with global supply experience

- Custom tooling for unique part geometries and multistage dies

- Consistent export-grade quality with traceability

- Flexible batch sizes from 1,000 pcs to 100,000 pcs

- Strong documentation support: PPAP, ISIR, IMDS, REACH/RoHS

- Custom barcoded, bubble-wrapped, or tray-based packaging

- Rapid prototyping and transparent communication cycle

Frequently Asked Questions (FAQs)

- Can you stamp OFC or oxygen-free Copper?

- Yes, we regularly work with C10200 and high-conductivity grades.

- Do you offer plating services?

- Yes. Tin, Nickel, Silver, or dual plating is available.

- What drawing formats do you accept?

- PDF, STEP, IGES, DWG, DXF, SolidWorks files.

- What’s your minimum order quantity?

- From 1,000 pcs depending on the part and size.

- Can you deliver stamped parts with insulation sleeves or washers?

- Yes, we offer partial assembly and insulation solutions.

- Do you have in-house tooling?

- Yes, our toolroom handles die manufacturing, maintenance, and trials.

- Can you support stamping on Copper alloys?

- Absolutely. We stamp pure and alloyed Copper grades.

- Do you conduct electrical conductivity testing?

- Yes, for critical components on request.

- What are your packaging options?

- Polybags, trays, anti-tarnish wraps, barcode cartons, and export pallets.

- Do you support third-party inspections?

- Yes, with SGS, Intertek, or buyer-nominated agencies.

Customer Testimonial

“We’ve been importing precision Copper earth tags and contact blades from this company since 2018. They’re reliable, technically sound, and deliver excellent quality consistently. The plating finish, burr-free edges, and packaging quality are outstanding. A dependable global supplier.” — George, New Jersey, USA

Glossary of Terms

- ETP Copper: Electrolytic Tough Pitch Copper, high conductivity with slight oxygen content

- OFC: Oxygen-Free Copper, used in high-purity, sensitive applications

- Blanking: Cutting out flat shapes from sheet

- Progressive Die: A tool that performs multiple operations sequentially

- IACS: International Annealed Copper Standard, benchmark for conductivity

Packaging and Shipping

Parts are packed with anti-tarnish paper or VCI wraps. Tray-based packing prevents deformation. Barcoded labeling for identification and traceability. Bulk orders are shrink-wrapped and palletized. All exports are supplied with HS codes, COOs, and packing lists for smooth customs clearance.

Related Terms:

- High conductivity Copper stamped parts

- Earth tag stamping India

- Electrical Copper contact blades

- Oxygen-free Copper stamping components

- Copper terminal and fuse link parts

- Progressive stamped Copper electrical hardware

- Copper stamping for motor and rotor components

- Custom plated Copper electrical stampings

Looking for high-precision Copper stamped components? Email or WhatsApp us for a quick reply and a quote.