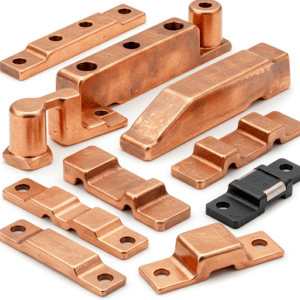

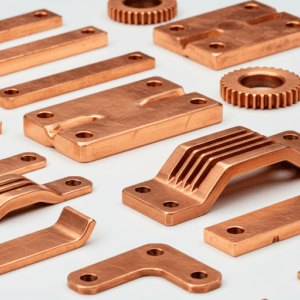

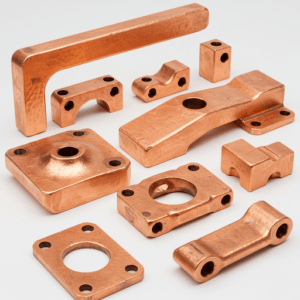

Copper Hot Forging | Copper Forged Parts | Copper Hot Stamped Components

Price: US$ 12.50/Kilogram

High Quality Copper Hot Forging Copper Forged Parts Copper Hot Stamped Parts !

We are one of the leading manufacturers and exporters of Copper Hot Forged Parts and Copper Hot forging Components from India. We have been supplying Copper Electrical Contacts, Copper Forged Connectors, and Transformer connectors Switchgear Components to the world market for many decades. Our specialization in High Conductivity Copper Forging makes us a trusted name in the electrical hardware industry. With over 30 years of global experience, we offer a complete end-to-end solution from raw material selection, die development, forging, machining, finishing to packaging. Our Copper Hot Stamped Parts are known for superior dimensional accuracy, high mechanical strength, and excellent electrical conductivity. We cater to a wide range of industries including switchgear, transformers, heavy electricals, and renewable energy sectors. Our facility in India houses modern forging equipment and CNC machining centers that allow us to deliver precision components with consistency and reliability.

Material Grades

We primarily work with the following High Conductivity Copper grades:

| Grade Name | Standard Equivalents | Conductivity (% IACS) | Typical Application |

|---|---|---|---|

| ETP Copper | ASTM B152 C11000 / IS 191 / BS EN 13601 | 98-100% | Electrical Contacts, Busbars |

| OFHC Copper | ASTM B187 C10200 | 101% | High-Purity Applications |

| DHP Copper | ASTM B152 C12200 | 90-95% | Plumbing, Industrial |

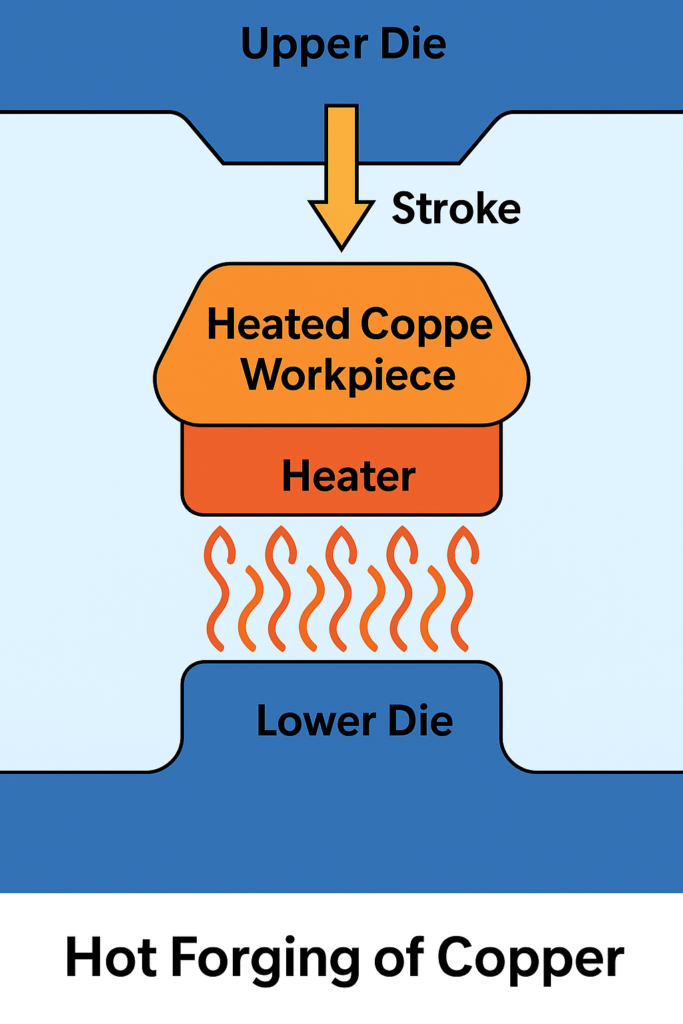

Manufacturing Process

Copper Hot Forging (also called Copper Hot Stamping) involves heating Copper billets to temperatures between 700°C and 900°C, followed by precision pressing using dies to shape the part. The process enhances grain structure, improves mechanical strength, and results in excellent surface finish and dimensional stability. Post-forging, the parts undergo trimming, heat treatment (if required), CNC machining, deburring, and surface finishing. Our Copper stamping and Stainless Steel hot stamping experience goes back 3 decades and we can offer heavy duty Copper hot forging and hot stamping parts. We also offer Brass stamping and forging.

Machinery Used

- Friction Screw Presses (300-1000 tons)

- Drop Forging Hammers

- Induction Heating Furnaces

- CNC Machining Centers

- Trimming Presses

- Shot Blasting Units

Typical Parts Produced

- Copper Electrical Contacts

- Copper Connector Terminals

- Copper Transformer Contacts

- Copper Switchgear Components

- Copper Busbars

- Copper Fuse Contact Copper fuse Holders, Fuse Elements and Strips

Industries We Serve

- Electrical & Power Distribution

- Switchgear & Control Panels

- Renewable Energy

- Railways & Locomotive Electricals

- Industrial Automation

- Defence & Aerospace (on request)

Finish Options

- Bright Natural Finish

- Electro Tin Plating

- Nickel Plating

- Silver Plating (optional)

- Anti-Tarnish Coatings

Tolerances

We offer precise tolerances as per customer drawings:

- Forging Tolerance: ±0.3 mm (standard)

- Machining Tolerance: up to ±0.05 mm

- Hole Position Accuracy: ±0.1 mm

Size Range / Dimensional Table (Representative)

| Part Type | Min Dia (mm) | Max Dia (mm) | Length Range (mm) | Typical Weight (g) |

| Fuse Contact | 8 | 35 | 15 – 150 | 20 – 300 |

| Connector Lug | 10 | 50 | 25 – 200 | 40 – 500 |

| Switchgear Contact | 12 | 60 | 20 – 250 | 100 – 900 |

Turnaround Time

Our standard delivery time is 4 to 6 weeks from approval of drawings and receipt of order. We offer flexible timelines for urgent requirements.

Performance Metrics

- Electrical Conductivity: 98-101% IACS

- Tensile Strength (Forged ETP): 210-260 MPa

- Elongation: 30-35%

- Surface Finish (Post Machining): Ra 1.2 – 3.2 µm

Why Choose Us?

- 30+ Years of Global Export Experience

- In-house Tool & Die Development

- Fast Turnaround Times (4-6 weeks typical)

- Fully Customized Production & Packaging

- Strong Communication and Documentation Support

- Flexibility in MOQs and Batch Sizes

- Export to USA, Germany, UAE, South Africa, and Asia-Pacific

Packaging & Shipping

Parts are packed in:

- Custom-labeled corrugated boxes

- Vacuum-sealed poly bags (for plated parts)

- Export-worthy wooden crates with fumigation Shipping via air or sea, based on customer requirements. Drop shipping available.

Customer Testimonials

Michael D., USA: “We rely on them for all our Copper Hot Stamped and Hot forged parts and Copper connectors. Excellent quality, timely delivery, and personalized support. We’ve never had to look elsewhere.”

Typical Q & A

- What is Copper Hot Forging?

- It’s the process of shaping heated Copper parts using pressure dies.

- What are the advantages over machining from bar stock?

- Better grain structure, less material wastage, improved mechanical strength.

- Can you meet ASTM and DIN standards?

- Yes, we produce as per ASTM B152, DIN EN 13601, IS 191, and others.

- Can you supply plated parts?

- Yes, tin, nickel, and silver plating available.

- Do you provide machining as well?

- Yes, we offer CNC turning, drilling, and slotting.

- Can you develop samples?

- Absolutely. Sample development takes 10-15 working days.

- What about custom packaging?

- Available. We pack with customer logos and barcodes if needed.

- Do you offer PPAP or FAI?

- Yes, on request.

- Can you handle small batch runs?

- Yes, we are flexible with batch sizes.

- What is your defect rate?

- Typically < 0.5%, with full quality inspection protocols.

Glossary of Terms

- IACS: International Annealed Copper Standard

- ETP: Electrolytic Tough Pitch Copper

- OPM %: Operating Profit Margin

- PPAP: Production Part Approval Process

- FAI: First Article Inspection

- Ra: Surface roughness average (in micrometers)

Related Parts and terms: Copper Forging Manufacturer, Copper Electrical Connectors, Copper Terminal Forgings, Copper Hot Stamping, Custom Copper Forged Parts, Copper Lugs Manufacturer India, Copper Contact Exporters, Copper Forged Component Supplier

Looking for a reliable supplier of high-performance Copper Forged Parts? Email us for a brochure, ask for a quote, or call/WhatsApp us today for personalized support and pricing!