Copper Electrical Contacts | Copper Connectors | Copper Electrical Connectors |Copper Contacts

Copper Electrical Contacts & Copper Electrical Connectors

We are one of the leading manufacturers and exporters of Copper Electrical Contacts and Copper Electrical Connectors from India. We have been supplying high-performance Copper-based components to the world market for many decades. Our specialization lies in designing, producing, and delivering precision-made electrical Copper contacts and Copper connectors that meet stringent international standards. With in-house capabilities ranging from forging, stamping, bending, machining, to plating, we cater to OEMs, electrical panel builders, switchgear manufacturers, and power distribution industries across continents. Our facility in Jamnagar, India is equipped with modern CNC, VMC, roll threading, and hydraulic power press machinery, ensuring seamless production and quick turnaround. Whether it is a standard component or a completely customized part with specific finish and dimensions, we offer unmatched flexibility and support. Our 30+ years of experience, global exposure, and dedication to quality make us a trusted name in Copper Contact solutions.

We also make Copper parts and Copper components like Copper Busbar Contacts, Silver Plated Copper Lugs, Copper pressed terminals, Copper Electrical Terminals, Flat Copper Bars for Switchgear, Pressed Copper Jumpers, Copper battery lugs, Copper battery contacts,

Copper Electrical Contacts

Copper Electrical Contacts are typically used as conducting elements in relays, switches, breakers, and busbar interconnects. They are precision-cut, pressed, or machined from high-conductivity Copper grades such as ETP (C11000), OFC (C10200), or Silver-bearing Copper (C16200). These parts ensure minimal resistance and optimal electrical performance under high current loads. Contacts may also be Silver plated for enhanced conductivity and corrosion resistance.

Manufacturing Process: Pressed from busbars, CNC machined, punched, or cold forged. Heat treatment and surface finish as per requirement.

Machinery Used: CNC/VMC, hydraulic press, stamping machine, deburring and polishing units.

Finish Options: Natural Copper, Electro-Tinned, Nickel Plated, Silver Plated, Anti-tarnish coated.

Applications: Electrical panels, switchgears, power control modules, MCCBs, disconnectors.

Typical Tolerances: ±0.1 mm for stamped parts; up to ±0.05 mm for CNC machined components.

Standards: ASTM B187, DIN EN 13601, IS 1897.

Turnaround Time: 4–6 weeks including packaging.

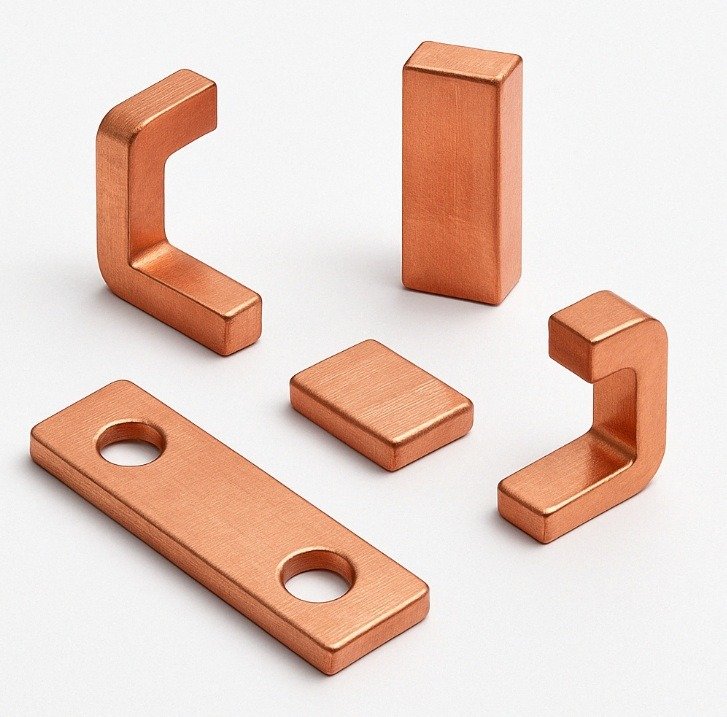

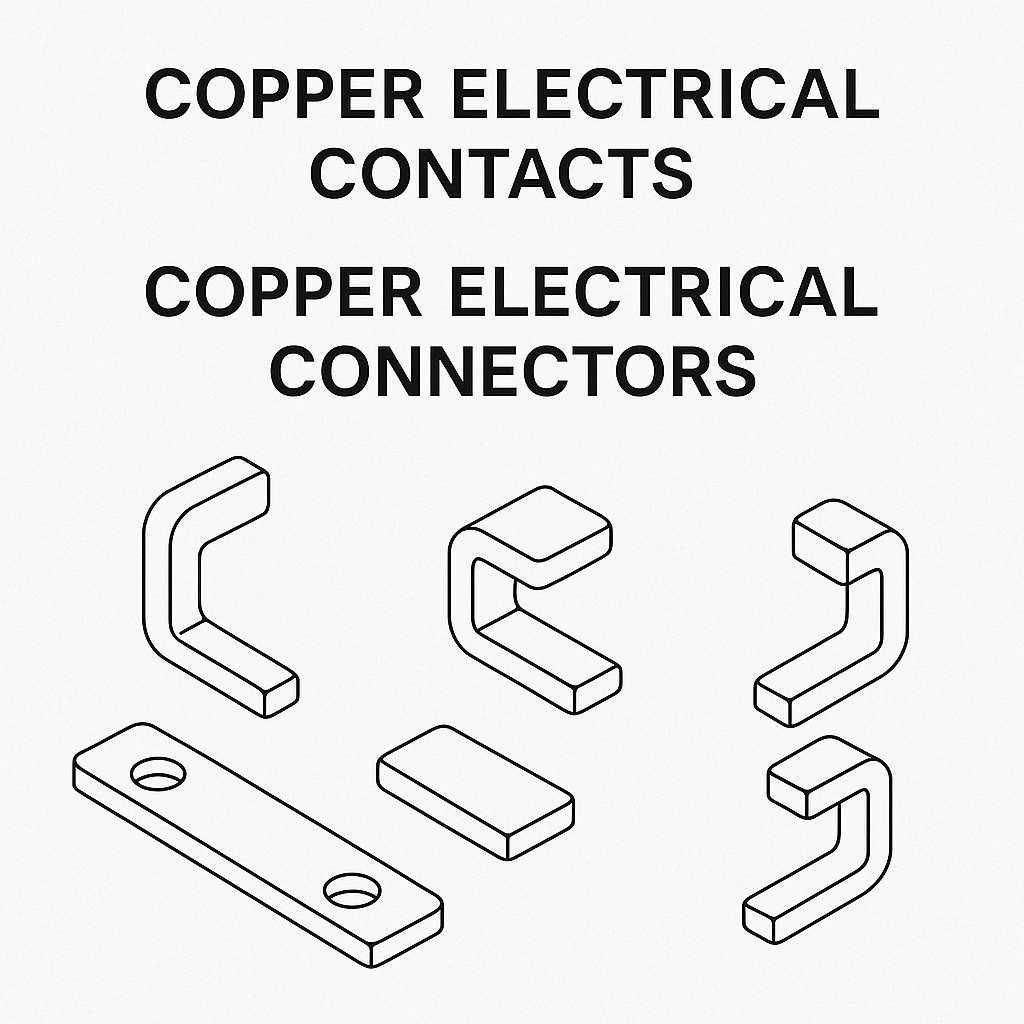

Copper Electrical Connectors

Copper Electrical Connectors serve as mechanical joining and conducting elements between two or more conductors. These are typically L, U, or Z-shaped profiles pressed or bent from Copper busbars to customer specifications. High dimensional integrity and conductivity are critical.

Material Grades: C11000 (ETP), C10100 (OFE), C12200 (DHP for brazed assemblies).

Manufacturing Process: Pressing, bending, and precision drilling. Silver plating for low contact resistance.

Machinery Used: Bending presses, hydraulic cutters, punching units, surface polishing machines.

Finish Options: Plain Copper, Silver Plated, Nickel Plated.

Applications: Control panels, substations, busduct systems, electric vehicles, battery banks.

Industry Standards: IEC 60947, UL486A/B, JIS H3100.

Typical Parts Produced: Terminal lugs, busbar links, jumper connectors, T and L connectors.

Line Drawing Sample (Illustrative): [Insert Infographic Here]

Size & Dimension Table:

| Part Type | Thickness (mm) | Width (mm) | Length (mm) | Hole Diameter (mm) |

|---|---|---|---|---|

| L-Connector | 3.0 | 20 | 50 | 6.5 |

| Flat Contact Bar | 2.0–5.0 | 15–40 | 30–150 | 5–9 |

| Z-Connector | 3.5 | 25 | 60 | 8.0 |

Why Choose Us

- Faster turnaround with flexible MOQ

- Global exports to over 20 countries

- Custom labeling and packaging with logo

- Technical drawing validation support

- 100% in-house production ensures traceability

Performance Metrics

- Contact resistance: < 0.2 mΩ

- Current carrying capacity: Up to 800 Amps

- Plating thickness: 5–10 microns (Silver)

- Mechanical bend strength tested to 10,000 cycles

Customer Testimonial “We have been sourcing our Copper Electrical Connectors from this supplier for over 5 years. Their quality is consistent, packaging is professional, and lead times are always reliable. Excellent communication and technical understanding.” – John M., Ohio, USA

Typical Customer Q&A

- Do you offer custom dimensions? Yes, fully customizable.

- What is your plating thickness? Typically 5–10 microns.

- MOQ for exports? 500 pcs or as mutually agreed.

- Can you supply with UL marking? Yes, on request.

- Do you offer CAD drawings for approval? Yes.

- Can we get our logo on the part? Yes.

- Do you offer PPAP documentation? Available for OEM clients.

- Can we get samples? Yes, paid samples can be shipped.

- Is third-party inspection allowed? Yes.

- Do you supply with barcoding? Yes, available.

Packaging and Shipping Parts are individually poly-bagged or packed in anti-tarnish paper with customized labeling. Export-grade corrugated cartons and fumigated pallets used as per ISPM-15 norms. Air and sea shipments handled by our logistics team.

Glossary of Terms

- ETP Copper: Electrolytic Tough Pitch, 99.9% pure.

- OFE Copper: Oxygen Free Electronic, premium conductivity.

- Plating: Electrochemical deposition of protective metal layer.

- Contact Resistance: The resistance at the interface of two contacts.

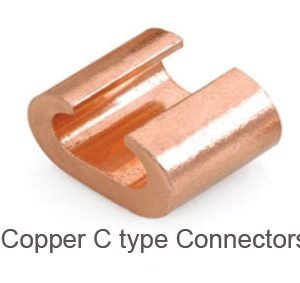

Related Copper Parts and Copper components : Copper Busbar Contacts, Silver Plated Copper Lugs, Copper Electrical Terminals, Flat Copper Bars for Switchgear, Pressed Copper Jumpers, Copper C type Compression Connectors, Copper contacts, Copper lay in lugs etc

Email us for a detailed quote or brochure. Call or WhatsApp us on +91-98250-12345. We respond within 24 hours with technical and commercial support.