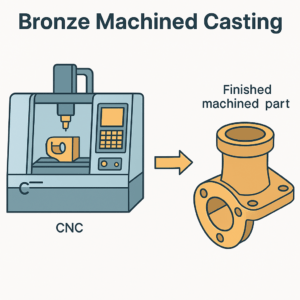

Bronze Machined Casting, Bronze Parts, Bronze Components

Price $ 11.40/kilogram, FOB Email to order.

Bronze casting combined with precision machining offers exceptional versatility in producing high-performance components for various industrial applications. Our manufacturing alloy guide covers Bronze alloy specifications, casting methods, and machining processes used in manufacturing precision components. Our Bronze casting foundry and CNC machine shop churn high quality precision Bronze castings , Bronze parts and Bronze components for international usage. We have been casting and machining various Bronze, Leaded Bronze, Aluminium Bronze, Phosphor Bronze, Manganese Bronze Alloys for 3 decades.

Bronze Alloy Specifications

| US Grade (UNS) | UK/EU Grade | Common Name | Composition | Properties | Applications |

|---|---|---|---|---|---|

| C83600 | CC480K / LG2 | 85-5-5-5 Bronze (Gunmetal) | 85% Cu, 5% Sn, 5% Pb, 5% Zn | Excellent machinability, Good pressure tightness | Valves, Pumps, Gears, Electrical connectors, Boat and marine hardware, Hotline clamps, Transformer Ground clamps, Transformer terminals, Transformer ground connectors, Transformer spades, NEMA spaced Transformer terminals and spades, Spade terminals, Bronze Vise clamps, grounding and Bonding connectors, Bronze connectors for switchgears , Bronze tees, Elbows, Unions, Hex Nipples, Hose nipples, Hose barbs, |

| C90300 | CC333G / LB1 | Navy Bronze G | 88% Cu, 8% Sn, 4% Zn | High strength, Corrosion resistant | Marine components, Propellers, Marine valves and seacocks, Hull fittings and through-hull components |

| C95400 | CC331G / AB2 | Aluminum Bronze | 85% Cu, 11% Al, 4% Fe | High strength, Wear resistant | Bearings, Worm gears, Bronze Hotline clamps ,Aluminum Bronze Casting for Transformer Connectors and Spades , Transformer ground lugs, Transformer Ground Clamps, |

| C93200 | PB102 / LB2 | SAE 660 | 83% Cu, 7% Sn, 7% Pb, 3% Zn | Self-lubricating, Good wear resistance | Bushings, Sleeve bearings, Valve fittings, |

| C86300 | CC762S | Manganese Bronze | 65% Cu, 25% Zn, 5% Al, 3% Mn | High strength, Good wear resistance | Heavy-duty bearings, Gears, Pipe fittings, hose fittings, bronze fittings for hydralics, Manifolds, |

| C92200 | CC491K / LG4 | Navy M Bronze | 88% Cu, 6% Sn, 1.5% Pb, 4.5% Zn | Good machinability, Corrosion resistant | Pumps, Valves, Marine hardware, electrical components, Hardware parts, |

| C95500 | CC333G / AB2 | Nickel Aluminum Bronze | 81% Cu, 9% Al, 4.5% Ni, 4% Fe | Excellent strength and corrosion resistance | Marine propellers, Pump impellers, Bronze acorn clamps, Bronze grounding clamps, Transformer Spade terminals, Vise Connectors, Substation Connectors, Electrical hardware, Hotline clams, Bronze flanges, Flanged nuts, |

| C87600 | CC754S | Silicon Bronze | 95% Cu, 4% Si, 1% Mn | High strength, Excellent corrosion resistance | Marine fittings, Thru hulls, Architecture, Vise connectors, Pipe fittings, Worm wheels Spur gears, Helical gears, Gear blanks, Bevel gears |

| C91300 | CC482K | Tin Bronze | 91% Cu, 9% Sn | High wear resistance, Low friction | Gears, Bearings, Bronze Bushings, Hose Nipples, Hose barbs, hose fittings, Electrical connectors, Wedge connectors, Lay in Lugs, Lay in connectors, Lay in clamps, |

| C96400 | CC334G | Copper-Nickel Bronze | 70% Cu, 30% Ni | Superior corrosion resistance | Marine valves, Pump components, Bronze Flanges, Pipe flanges, Sealing rings, Bronze washers, Pipe fittings, |

| C95800 | CC335G | Nickel Aluminum Bronze | 81% Cu, 9% Al, 5% Ni, 4% Fe | High strength at elevated temperatures | Aerospace components, Propellers, Valve bodies, Gate valve components, Globe valve parts, Ball valve seats ,Valve stems and guides |

| C90700 | CC497K | Tin Bronze | 89% Cu, 11% Sn | High strength, Good bearing properties | Heavy-duty bearings, Worm wheels |

| C94700 | CC493K | Nickel-Tin Bronze | 86% Cu, 8% Sn, 4% Ni, 2% Zn | Excellent wear resistance | Steam fittings, Valve seats, Pump casings, Pump Impellers Wear rings, Pump shaft sleeves, Stuffing box bushings, Pump end covers, |

| C95200 | CC330G | Aluminum Bronze | 88% Cu, 10% Al, 2% Fe | Good strength and ductility | Bearings, Gears, Bushings, Transformer grounding clamps , Bus bar components, Terminal connectors, Cable glands, Junction box components, transformer tank connectors, Grounding and bonding connectors, Grounding clamps, Earthing clamps, |

| C95900 | CC333G | Nickel Aluminum Bronze | 78% Cu, 13% Al, 5% Ni, 3% Fe | Maximum strength and hardness | Heavy-duty marine applications |

Bronze Casting Methods

Bronze Sand Casting, Bronze Green Sand Casting

Most common method for bronze components, offering:

- Suitable for large components up to several tons

- Complex geometries possible

- Cost-effective for low to medium production runs

- Typical tolerance: ±0.5mm per 25mm

Bronze Investment Casting (Lost Wax Casting)

Preferred for precision components:

- Excellent surface finish

- High dimensional accuracy

- Complex internal passages possible

- Typical tolerance: ±0.1mm per 25mm

Bronze Centrifugal Casting

Ideal for cylindrical components:

- Dense, high-quality castings

- Excellent concentricity

- Suitable for bushings and sleeves

- Typical tolerance: ±0.25mm per 25mm

Bronze Continuous Casting

For bar stock and tubes:

- Consistent material properties

- Good for high-volume production

- Excellent material yield

- Typical tolerance: ±0.2mm per 25mm

CNC Machining Operations

| Operation | Description | Typical Tolerances | Surface Finish |

|---|---|---|---|

| CNC Turning | For cylindrical components, facing, threading | ±0.025mm | Ra 0.8-3.2µm |

| CNC Milling | Flat surfaces, pockets, profiles | ±0.05mm | Ra 1.6-6.3µm |

| Drilling | Holes, bores, tapping | ±0.1mm | Ra 3.2-12.5µm |

| Boring | Precision internal diameters | ±0.02mm | Ra 0.4-1.6µm |

Machining Parameters for Bronze

- Cutting Speed: 60-120 m/min

- Feed Rate: 0.1-0.5 mm/rev

- Depth of Cut: Up to 5mm

- Tool Material: Carbide or HSS

- Cooling: Flood coolant recommended

Quality Control Measures

- Chemical composition analysis

- Mechanical property testing

- Non-destructive testing (NDT)

- Dimensional inspection

- Surface finish measurement

- Pressure testing where applicable

Applications for Bronze Cast machined parts and Bronze machined Components

- Marine components and fittings 9

- Marine Grade Casting, Pump impellers in AB1 and AB2 , ALBC 1 , ALBC 2 , ALBC 3 , ALBC 4

- Industrial valve bodies and trim

- Bearing bushings and wear plates

- Pump components

- Gears and worm wheels

- Architectural hardware

Design Considerations

- Draft angles: Minimum 1° for external surfaces, 2° for internal surfaces

- Wall thickness: Minimum 3mm recommended

- Corner radii: Minimum 3mm to prevent stress concentration

- Machining allowance: 2-3mm on critical surfaces

- Parting line location: Consider for optimal casting quality

Check our Bronze Shell molding parts and castings and Gunmetal Casting LG2 Casting CDA 836 Bronze Casting

Q: What is Bronze Machined Casting, and why is it used?

A: Bronze Machined Casting is a precision manufacturing process used to produce high-quality Bronze Parts and Bronze Components. The process involves melting and pouring molten Bronze into a mold, which is then machined to meet exact specifications. This technique is widely used in industries requiring durable, corrosion-resistant, and precisely engineered Bronze Components for applications such as electrical, marine, and mechanical engineering.

Q: What are the benefits of Bronze Machined Casting over other metal casting methods?

A: Bronze Machined Casting offers several advantages:

- High Strength and Durability: Bronze is known for its toughness and long-lasting performance.

- Corrosion Resistance: Excellent resistance to moisture, chemicals, and extreme environments.

- Precision Machining: Ensures exact dimensions, reducing the need for additional processing.

- Superior Conductivity: Ideal for electrical Bronze Parts used in grounding and other applications.

- Wear Resistance: Suitable for mechanical components exposed to friction and heavy use.

Q: What types of Bronze Machined Casting techniques are commonly used?

A: Several techniques are employed for Bronze Casting, including:

- Sand Casting: A cost-effective method for producing large, complex Bronze Components.

- Investment Casting: Provides high precision and detailed surface finishes.

- Centrifugal Casting: Used for cylindrical Bronze Parts, ensuring high density and strength.

- Continuous Casting: Ideal for producing uniform and defect-free Bronze Bars and Rods.

Q: What industries rely on Bronze Machined Casting?

A: Bronze Parts and Bronze Components are essential in various industries, including:

- Aerospace: Used in bearings, bushings, and landing gear components.

- Marine: Preferred for propellers, valves, and corrosion-resistant fittings.

- Automotive: Applied in engine components, gears, and braking systems.

- Electrical: Used in conductive Bronze Components for switches, connectors, and grounding systems.

- Industrial Machinery: Utilized in heavy-duty bearings, gears, and wear-resistant machine parts.

Q: What are some common Bronze Alloys used in Machined Casting?

A: Various Bronze Alloys are used depending on the application, including:

- Phosphor Bronze: High strength, excellent wear resistance, used in electrical and mechanical components.

- Aluminum Bronze: Superior corrosion resistance, ideal for marine and industrial use.

- Silicon Bronze: Strong, corrosion-resistant, commonly used in architectural and artistic applications.

- Lead Bronze: Good machinability, used in heavy-duty bearings and bushings.

Q: How do Bronze Machined Casting and Machined Bronze Parts compare to other metals?

A: Compared to other metals like Steel, Aluminum, Brass, and Copper, Bronze Components offer:

- Higher Corrosion Resistance: Especially in marine and industrial environments.

- Better Thermal and Electrical Conductivity: Ideal for electrical applications.

- Lower Friction and Wear: Preferred for mechanical moving parts.

- Easier Machinability: Allows for complex and precise part manufacturing.

Q: What are the quality control measures in Bronze Machined Casting?

A: To ensure the highest standards, manufacturers follow strict quality control procedures, including:

- Material Testing: Verifying Bronze Alloy composition for optimal performance.

- Dimensional Inspections: Ensuring tight tolerances and precision.

- Non-Destructive Testing (NDT): Detecting internal defects or inconsistencies.

- Surface Finish Inspection: Guaranteeing smooth and defect-free Bronze Components.

Q: How can I choose the right Bronze Machined Casting supplier?

A: When selecting a supplier for Bronze Machined Casting, consider the following factors:

- Experience and Expertise: A supplier with extensive knowledge in Bronze Casting ensures quality output.

- Certifications and Standards: Look for compliance with industry standards like ISO, ASTM, or UL.

- Customization Capabilities: Choose a manufacturer that can produce custom Bronze Parts to your specifications.

- Lead Time and Reliability: Ensure timely delivery without compromising quality.

By choosing the right Bronze Machined Casting supplier, you can optimize the performance, durability, and precision of your Bronze Components for any application.