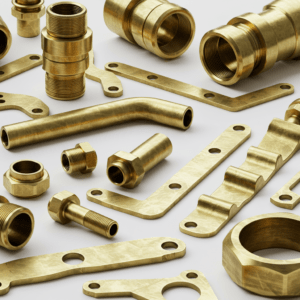

Brass Hot Forging | Brass Hot stamping | Brass Stamped Parts | Brass Stamped Components | Brass Forged Fittings

Brass Hot Forging Fittings | Brass Hot Stamped Parts | Brass Hot Stamped Fittings| Brass hot Stamped Components | Brass Forged Fittings

PRICE $ 10.20/Kilogram

We are one of the leading manufacturers and exporters of Brass Hot Forged and Hot Stamped Components from India. We have been supplying precision Brass forged parts, stamped fittings, and custom Brass components to the global market for many decades. With advanced forging hammers, high-tonnage presses, in-house die manufacturing, and post-processing capability, we offer durable, corrosion-resistant and aesthetically finished Brass parts. Our strength lies in serving critical industries like electrical hardware, plumbing fittings, instrumentation, and automotive systems with customized solutions, fast turnaround, and globally accepted quality standards. Our company is a leading manufacturer and supplier form India of Brass pressed and stamped parts , Stainless Steel hot stamped fittings , Copper Hot stamping and Copper Sheet metal pressed stamped parts.

Overview

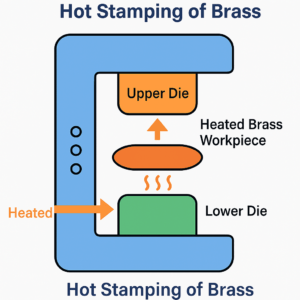

Brass hot forging and hot stamping involve heating Brass billets or slugs and deforming them under controlled force to achieve high-strength, dimensionally accurate components. Compared to cast or machined parts, forged Brass exhibits better grain alignment, superior mechanical properties, and minimal porosity. Forged parts are ideal for applications requiring leak-proof performance, structural integrity, and surface finish excellence. Our manufacturing process supports small to mid-size parts with complex geometries and tight tolerances.

Material Grades and Specifications

We utilize high-quality Brass grades that conform to international forging and stamping standards:

| Grade | Standard Equivalents | Characteristics | Typical Applications |

|---|---|---|---|

| IS 319 Type I | IS 319, ASTM B124 | Free cutting, general-purpose forging | Electrical parts, terminals |

| CW617N | EN 12165, BS 2874 CZ122 | Hot forged, dezincification-resistant | Plumbing, sanitary fittings |

| CW614N | EN 12164, ASTM B16 | Machinable, good forging characteristics | Instrumentation, auto connectors |

| C37700 | ASTM B124 | Excellent forging behavior | Valves, glands, mechanical fittings |

Mechanical Properties – Typical for CW617N Brass Forgings

| Property | Value |

| Tensile Strength | 400–500 MPa |

| Yield Strength | 160–300 MPa |

| Elongation | 10–20% |

| Hardness (HB) | 80–100 HB |

| Density | 8.4–8.6 g/cm³ |

Manufacturing Process

- Raw Brass rods or billets are cut to size and preheated (650–800°C)

- Forging takes place using high-tonnage presses or power hammers

- Trimming, flash removal, and cooling operations follow

- Post-forging heat treatment (annealing) and straightening

- Final operations: CNC machining, threading, drilling or polishing

- Quality checks: dimensional, hardness, microstructure, visual

Machinery Used

- 250T to 1000T Hydraulic Forging Presses

- Pneumatic & Power Hammers (1T–3T)

- Induction/Resistance Heating Furnaces

- Trimming and Coining Presses

- CNC Turning and Vertical Milling Centers

- Hardness Tester, Gauges, Profile Projector, Microscope

Finish Options

- Shot Blasted / Matte Finish

- Natural Polished Brass

- Chrome or Nickel Plated (as per customer spec)

- Lacquer Coated / Passivated

Industries Using Brass Forged & Stamped Components

- Electrical and Cable Termination Hardware

- Plumbing & Sanitary Hardware

- Automotive Fuel, Brake, and Connector Systems

- Gas & LPG Fittings and Safety Components

- Industrial Valves and Flow Components

- Instrumentation and Measuring Devices

Typical Parts Produced

- Brass Forged Cable Lugs

- Brass Bushes, Spacers, and Washers

- Valve Bodies and Bonnet Components

- Elbows, Tees, Unions, and Compression Nuts

- Forged Earth Tags and Terminal Bases

- Male-Female Brass Threaded Inserts , We also offer DZR brass fittings

Dimensional Range and Tolerances

| Feature | Range / Tolerance |

| Forging Weight | 10 g to 5.0 kg |

| Outer Diameter | 8 mm to 100 mm |

| Threading Tolerance | 6g, 6H, or custom as per spec |

| Flatness | ±0.1 mm per 100 mm |

| Surface Finish (Ra) | Up to 1.6 µm (machined) |

Turnaround Time

Standard lead time: 4 to 6 weeks post tool and sample approval. Samples can be provided within 12–15 working days. Repeat orders for standard items are executed within 2–3 weeks. We maintain tooling for repeatability and consistency.

Why Choose Us for Brass Forgings

- 30+ years of forging experience with global client exposure

- Ability to customize part geometry, alloy, and finish

- Complete in-house capability: die making to CNC to packing

- Flexible MOQs and short lead times for custom developments

- Skilled communication, documentation, and export logistics

- Packaging with client branding, barcode, or kitting

Frequently Asked Questions (FAQs)

- Can you develop parts from a physical sample?

- Yes, we provide reverse engineering and drawing generation.

- What alloy certifications do you provide?

- We supply chemical test reports from NABL-certified labs.

- Are your forgings RoHS/REACH compliant?

- Yes, all Brass used is RoHS and REACH compliant.

- Can you supply parts with machining?

- Yes, CNC turned, threaded, or drilled options are available.

- What’s the expected die life for Brass forging?

- 20,000 to 100,000 strokes depending on size and shape.

- Do you perform leak testing for plumbing parts?

- Yes, pressure and hydro tests can be arranged.

- What surface finishes are available?

- Natural, polished, nickel/chrome plated, lacquered.

- Can you supply barcoded packaging?

- Yes, with label formats provided by the customer.

- Do you offer heat treatment for Brass?

- Yes, including stress relief and soft annealing.

- Do you supply in knockdown kits?

- Yes, with multiple components packed together as per BOM.

Customer Testimonial

“We’ve been sourcing Brass forged fittings from this company since 2019. Their understanding of dimensional tolerances, plating specs, and export documentation is superb. Even complex parts with machining come out flawless. Highly recommended for quality and reliability.” — John R., Houston, USA

Glossary of Terms

- Forging: Compressing metal into desired shapes using high pressure

- Stamping: Forming or cutting metal via dies in press machines

- Ra (Roughness Average): A metric to define surface finish

- Die Life: Total number of parts a forging die can produce before replacement

- Flash Removal: Trimming excess material from forged parts

Packaging and Shipping

Parts are packed in polybags, trays, or foam depending on fragility. Bulk parts are boxed in corrugated cartons with barcoding and labels. Export packaging includes pallets or wooden crates with heat treatment markings. All consignments include packing lists, HS codes, batch traceability, and test certificates.

Related Terms:

- Brass forging manufacturer India

- Hot stamped Brass electrical fittings

- Machined Brass components for valves

- Brass pressure fittings exporter

- Precision forged Brass terminal lugs

- IS 319 forged Brass parts

- CW617N hot forged Brass fittings

Call to Action

Looking for precision Brass Forged or Hot Stamped Components? 📧 Email us and Send your drawings or RFQ today!